A quick Lesson in

Asphalt oil

Knowledge is power

Welcome to our asphalt 101 page! We believe that it is our duty to educate our customers so you are able to identify and understand what product you are using and why we you are using it. We want to be the hub for unbiased information at Read on Roads. This continues to be one of our core values that we operate with. If you don’t find what you are looking for here, give us a call and we would be more then happy to answer your questions.

Asphalt oil

vs

"Crude" based blade-mix oil

This has been one of the most common comparisons in the road maintenance industry. This has been a popular question solely due to cost. Crude based blade-mix oils can be sourced for less money when compared to a refined asphalt oil. One of the large issues we have found with crude based blade-mix oils is the lack of consistency. This continues to be the reason we don’t offer this product. We take pride in our ability to stand behind our products and services. With refined asphalt oils we can stand behind them because they meet the same spec for every load. With crude based blade-mix oil the residual asphalt content has the ability to vary from load to load. A big advantage for asphalt oil is the customizability of refined products. At Read on Roads we have the ability to design an oil specific to your aggregate and road. Another benefit to refined asphalt oil is the ability to control the residual asphalt found in the emulsion or cutback. Typically refined asphalt oils will contain higher levels of residual asphalt resulting in a stronger, longer – lasting end product.

ASphalt oil

- Product Consistency

- Higher Residual Asphalt

- Easier Access to Supply

- Highly Customizable

- Slightly More Expensive Than Crude Based Oil

Cutbacks vs Emulsions

These are two very common types of oil that are suspended in different petroleum diluents or emulsifiers. A cutback is classified as an oil suspended in a petroleum solvent. Traditionally these products do contain VOC’s. Emulsions on the other hand are an asphalt oil suspended in water. Even though emulsions are suspended in water they do contain low mounts of VOC’s. All of Husky Asphalt’s emulsions are designed to meet the Code of Practice for the Reduction of Volatile Organic Compounds (VOC) Emissions. Feel free to contact us regarding what oil should be used depending on the application.

Identifying a product

"SC - 600"

When you are trying to identify a product there are a few good resources out there. However there are a couple things you can look for. Typically these products start with a product type then followed by a number. The product type above, “SC” stands for ‘Slow-Cure”. This is a cutback asphalt that is rework-able after it has cured. The number that follows represents the “viscosity” of the product. The higher the number the “thicker” the oil. One important thing to note is that emulsions are numbered differently. The lower the number, like HF – 250, would be a more viscus product when compared to an HF – 1000 which has a low viscosity.

Testing Asphalt oil

Viscosity can be defined as a fluid’s resistance to flow. A common method for testing this is the Saybol Furol Viscosity Test. Based on the results this is how a product receives its viscosity number.

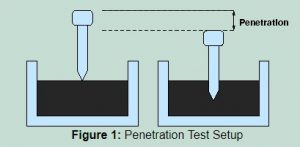

The penetration test measures an asphalt oils hardness or softness based on the penetration of the needle. The greater the penetration the softer the asphalt. For harder asphalt less penetration will occur.

The field coating test and water resistance test are used to determine the ability of the asphalt emulsion to coat the job aggregate, the ability of the emulsion to withstand mixing, and the ability to resist the washing action of water after the completion of mixing. This test is primarily used to identify medium-setting asphalt emulsions suitable for mixing with coarse-graded aggregates.

A distillation is performed to extract the light oil and water from an asphalt emulsion. The purpose of this test is to identify the amount of asphalt residue in the sample. Typically the result is seen as a percent of the weight of the asphalt sample.

This test is used to identify the charge associated with the asphalt emulsion. This test is done by submerging a positive electrode and a negative electrode into an emulsion sample. At the end of the test the electrodes are observed. If there is enough asphalt on the negative electrode the emulsion is cationic. If the asphalt is on the positive electrode then the emulsion is anionic.

Restorative Seals

Maltenes VS Asphaltenes

There is two common properties found in asphalts: Maltenes and Asphaltenes. Maltenes are the binding resin which presents flexibility and adhesion properties. Asphaltenes are responsible for a pavements rigidity. Combined, these properties allow pavement to be resilient to weather conditions and traffic volume. The goal with our restorative seals are to reintroduce these characteristics back into aging asphalt as a form of preventative maintenance.

Chemical Characteristics

Maltenes

Maltenes constitute the fraction of asphalt which is soluble in n-alkane solvent such as pentane and heptane. Their chemical characteristics are as follows:

- Contain smaller molecular weight versions of asphaltenes called “resins”

- Contain aromatic hydrocarbons with or without O, N and S (also called “first acidaffins”)

- Contain straight chained or cyclic unsaturated hydrocarbons called oleifins (also called “second acidaffins”)

- Contain cyclic saturated hydrocarbons known as naphthenes (also called “saturates”)

- Contain straight or branch chain saturated hydrocarbons (also “saturates”

- Their molecules are also known as “naphthene-aromatic

Chemical characteristics retrieved from: http://www.lloydminsterheavyoil.com/asphaltenes2.html

Asphaltenes

Asphaltenes are complex hydrocarbons having the following components:

Condensed aromatic hydrocarbons with side chains up to C30

- Hetero-aromatic compounds with sulfur present in benzothiophene rings and nitrogen in pyrrole and pyridine rings

- Bi- or polyfunctional molecules with nitrogen as amines, amides, and oxygen in groups such as: ketones, armides, phenols, and carbaxylic acids

- Metals nickel and vanadium complexed with pyyrole nitrogen atoms in porphyrin ring structures

Chemical characteristics retrieved from: http://www.lloydminsterheavyoil.com/asphaltenes2.html